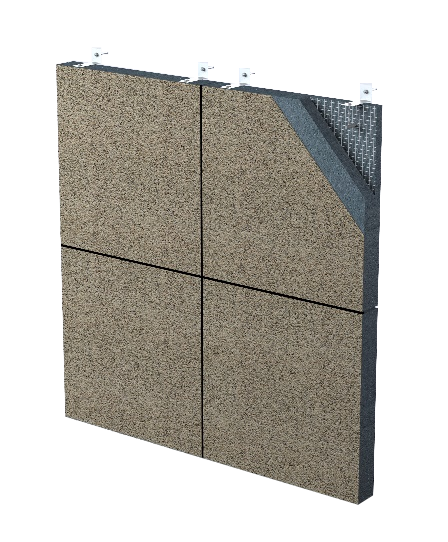

The silicon-based graphene insulation board is an A (A2)-class non-combustible insulation material formed through the composite of inorganic materials and organic insulation materials. It falls under the category of non-cement-based silicon-calcium composite technology and represents one of the most advanced insulation material technologies to date. This product is fabricated into insulation boards by leveraging the high-temperature and high-pressure forming mechanism of silicon-calcium and a distinctive secondary foaming process. This involves combining silicon-based ultra-fine inorganic materials with polystyrene particles, thereby endowing the product with remarkable properties such as low thermal conductivity, high toughness and strength, non-combustibility, and low water absorption. By utilizing connectors to position the silicon-based graphene insulation board within precast concrete walls, or by adopting safe and reliable techniques such as integrated prefabrication with reverse casting of the silicon-based graphene insulation board and integrated in-situ casting of insulation formwork, the silicon-based graphene insulation material and the main concrete wall are effectively integrated into an organic entity. This enables the realization of a wall system where wall construction and insulation installation occur concurrently, achieving insulation-structure integration and meeting the design requirement of having the same lifespan as the building. This technology effectively addresses issues such as the detachment, fire hazards, and cracking of exterior wall insulation in buildings. It can be applied to both new construction projects and the renovation of existing buildings. Currently, it stands as one of the key technical approaches promoted across various regions in China, and is particularly suitable for buildings with stringent fire protection and energy conservation requirements, such as ultra-low energy consumption buildings and near-zero energy consumption buildings.

-

01

Class A non-combustibility

Employing non-cement-based silicon-calcium composite technology, it attains Class A (A2) non-combustibility, exhibits a low thermal conductivity coefficient, and demonstrates excellent energy-saving performance.

-

02

High toughness and high strength

With a built-in double-layer steel mesh structure, the material demonstrates excellent compressive and tensile properties, as well as remarkable flexural and impact resistance capabilities. This allows for the synchronous pouring of the material together with concrete, effectively substituting for the external formwork.

-

03

Safe and reliable

It is fully adhered to the concrete wall without cavities and is complemented by necessary anchoring measures. This approach enables the integration of silicon-graphene insulation and the building structure, effectively addressing the issues of insulation detachment and hollowing in exterior building walls.

-

04

Short construction period

The insulation layer and the structure are monolithically cast. In comparison with the traditional external wall insulation system, this method reduces procedures such as secondary insulation construction, thus effectively shortening the construction cycle.

-

05

Low water absorption ratio

The distinctive secondary foaming and high-temperature and high-pressure processes render the material more compact. It exhibits a low water absorption rate and outstanding crack resistance properties. This effectively mitigates potential risks such as cracking, detachment, and water seepage, thereby enhancing long-term durability.

-

06

Simple construction

Similar to the traditional formwork process, but with simpler and more convenient construction procedures and easier operation. It can achieve large-sized specifications of 1.2m×3.0m and above, with fewer seams.

-

07Environmentally friendly

During the production process, no pollutants are emitted. All production waste is recycled at a rate of 100%. High-energy-consuming raw materials such as cement are not utilized. Moreover, the raw materials are free from formaldehyde, harmful volatile organic compounds (VOCs), etc. This product is characterized by its green, low- carbon, and environmentally friendly nature, ensuring greater confidence in its application within indoor environments.

-

08The integration of thermal insulation and structural functions

The silicon graphene insulation board can endure more than 160 thermal-rain cycles and upwards of 80 freeze-thaw cycles, which far surpasses the national regulations. The insulation material is integrally combined with the wall structure, truly attaining the objective of sharing the same service life as the building wall.

|

Parameter table |

Items |

|---|---|

|

Dry density, kg/m³ |

180-220 |

|

Compressive strength, MPa |

≥0.30 |

|

Tensile strength perpendicular to the plate surface, MPa |

≥0.20 |

|

Compressive elastic modulus, kPa |

≥20000 |

|

Flexural load , N |

≥3000 |

|

Flexural deformation, mm |

≥6 |

|

Water absorption rate by volume, % |

≤10 |

|

Thermal conductivity (25℃), W/(m·K) |

≤0.055 |

|

Softening coefficient |

≥0.8 |

|

Drying shrinkage rate, % |

≤0.3 |

|

Combustion performance grade |

Grade A (A2) |